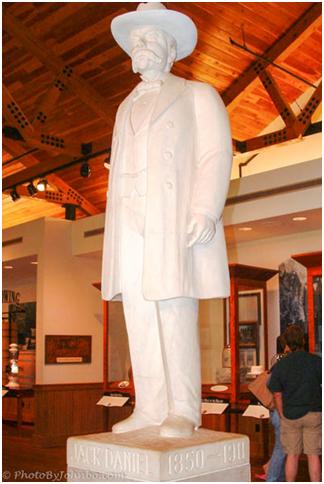

The history of the distillery and of Tennessee Whiskey, Jack Daniel style, is displayed in the large visitor center.

Nestled in South Central Tennessee, a 70-mile (112-km) drive from the bustling country music capital, Nashville, lays the small community of Lynchburg. With a population of only about 5,500 residents, there isn’t much to delineate Lynchburg from other small towns in the USA, aside from one major exception, the Jack Daniel Distillery. For those who enjoy the taste of Tennessee Whiskey, a tour of the distillery should be high on the list of places to visit while in the Nashville area. I submit for your consideration a few of the photographs taken during my own visit in 2007.

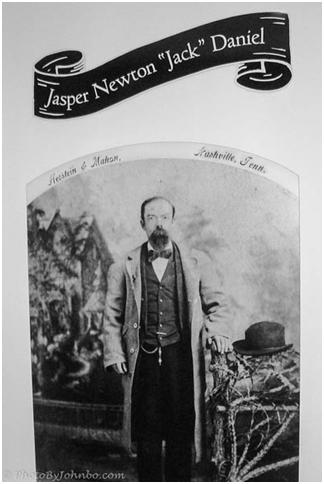

The history of the distillery starts with the biography of Jasper Newton Daniel, a short history of the master distiller is located here. At the age of 13, he purchased a distillery from the man who apprenticed him in the business. In 1866, he registered his distillery with the US government, the first in the nation to do so.

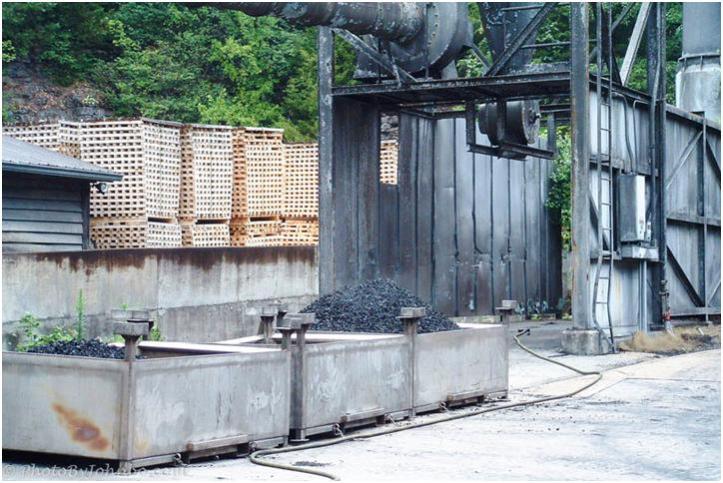

Output from the charcoal furnace awaits a trip to the filters. Stacks of fresh maple (in the back) will soon be turned into charcoal.

Tennessee whiskey distinguishes itself from bourbon and other whiskeys by its charcoal filtering process. Charcoal is made on site from maple stock in a huge furnace. The spirits are filtered through the charcoal giving the beverage its distinctly different flavor from bourbon. Jack moved to Cave Spring Hollow because he believed the water there to be superior. The distillery remains in the same location to this day.

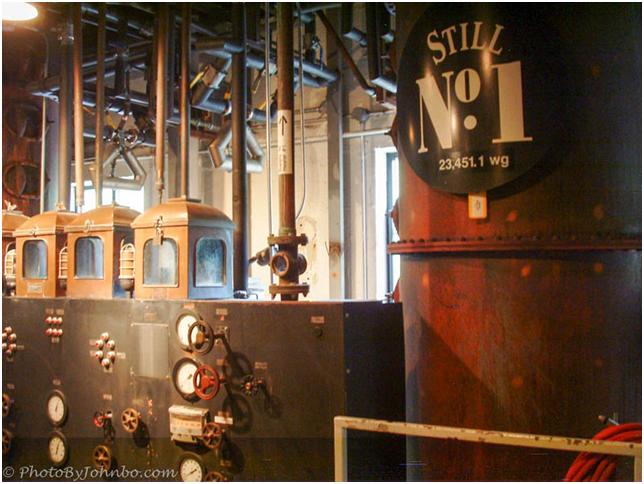

Traditionally corn, barley or rye is cooked in a “mash” and the alcohol is fermented out of the mash in a still, several of which are functional in the distillery.

The still heats the mash causing the alcohol to rise with the vapor. The cooled vapors are turned back into liquid and passed through additional processing. The distillery contains several storage buildings where oak barrels containing the fresh product are aged for about four years. Professional distillers sample the contents of the barrels as they near completion to determine when it’s time to send the barrel to the bottling plant, also located on the premises.

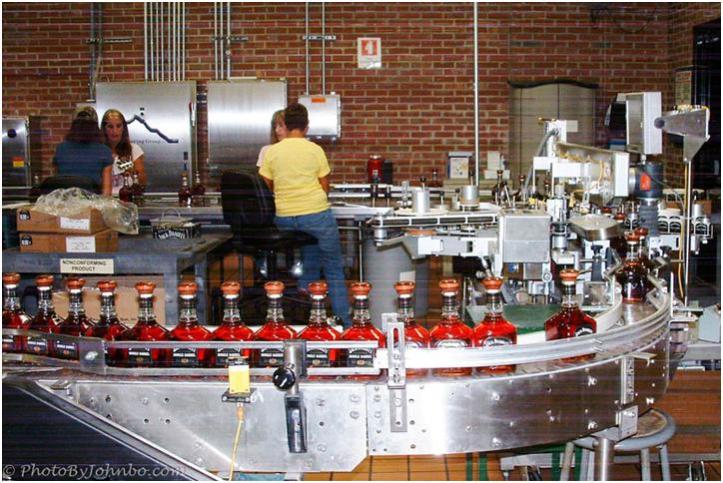

Bottles move down the assembly line heading toward final packaging.

One of the ironies of our tour is that Lynchburg is in a “dry” county. In 2007, no sampling of the product was allowed due to that county law. I noticed on the Jack Daniel website that they can now offer sampling tours for a “nominal fee.” I’m a bit confused by this because on the very same webpage, they still reference Moore County as dry.

A recent article in “The Tennessean” reports the distillery will spend more than $100 million USD to increase production and storage capacity so that production can keep up with demand and still remain in Lynchburg. The number of employees in the plant will grow from its current 430 by about 90 as the addition comes online.

John Steiner

I enjoyed a tour of the Jack Daniels place myself………bought a decanter fifth to sip on. Thanks for sharing (your photos, not your Jack).

We have a bottle of 1954 Gold Medal from there as well. Thanks for the comment.